Drill Jig and Fixture Design

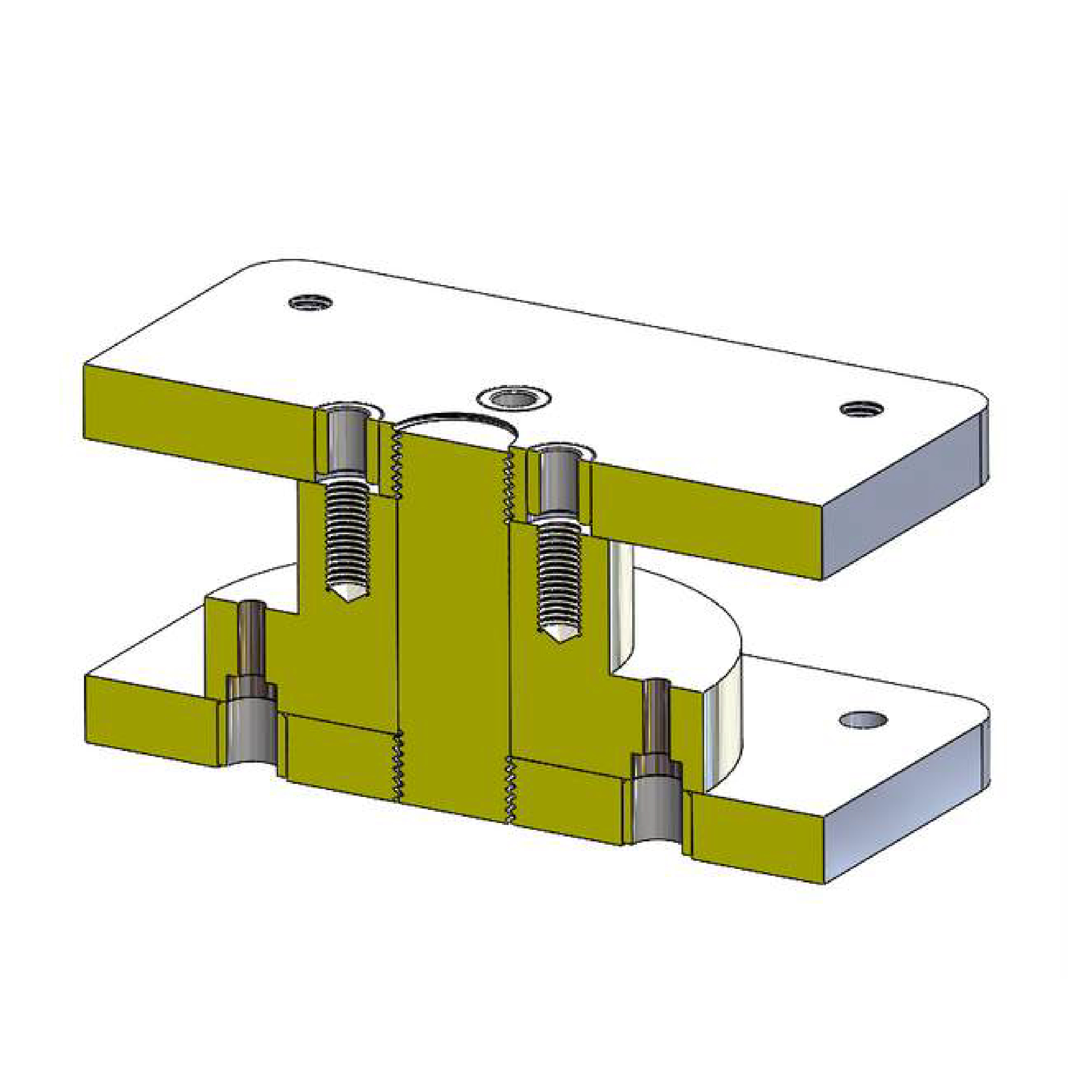

This drill jig and fixture project aimed to solve the problem of inconsistent hole alignment during flange part manufacturing. The system was engineered to provide a stable, repeatable, and time-efficient drilling process, ensuring every hole matched strict production tolerances. It was modeled using SolidWorks with precision in mind, built for high-volume production environments.

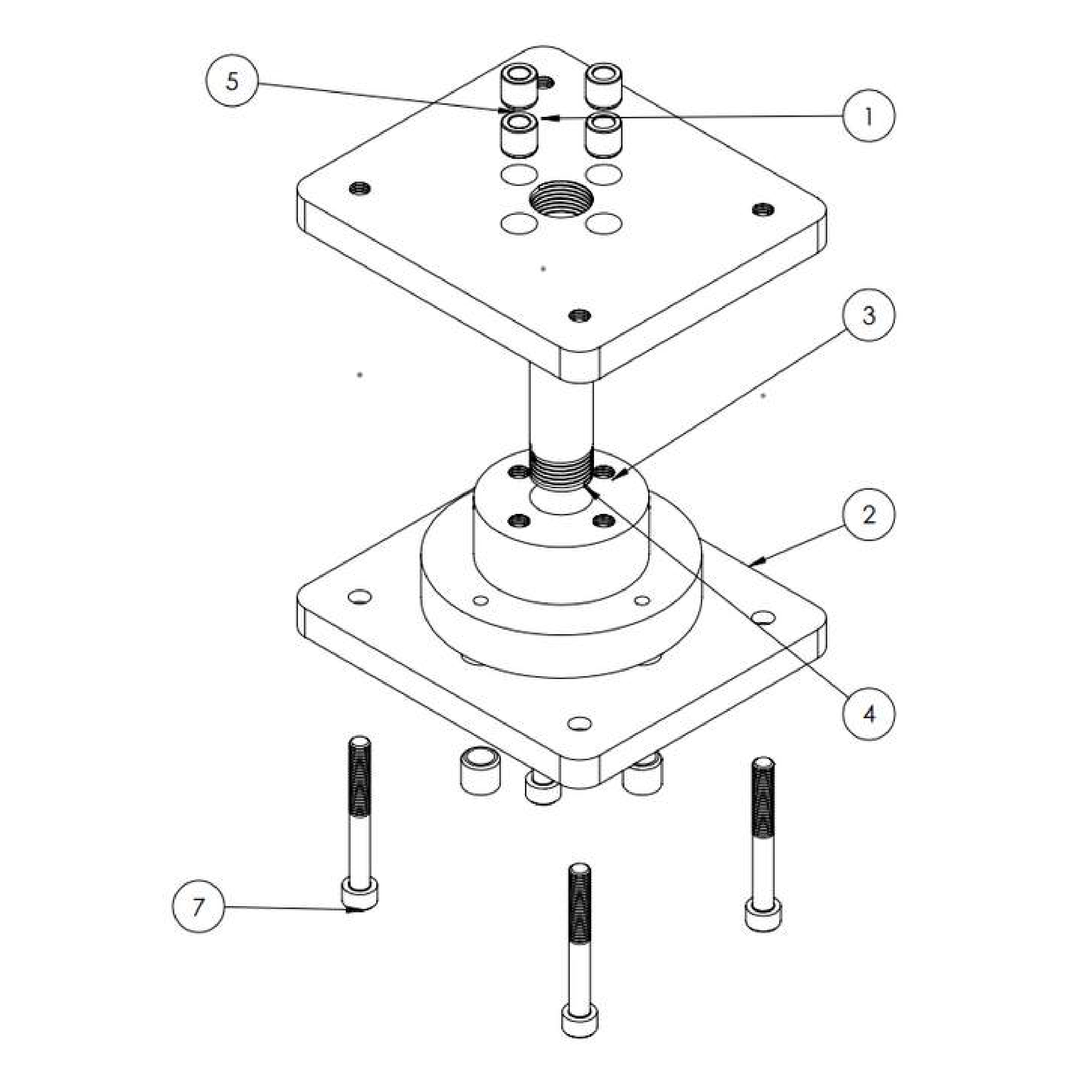

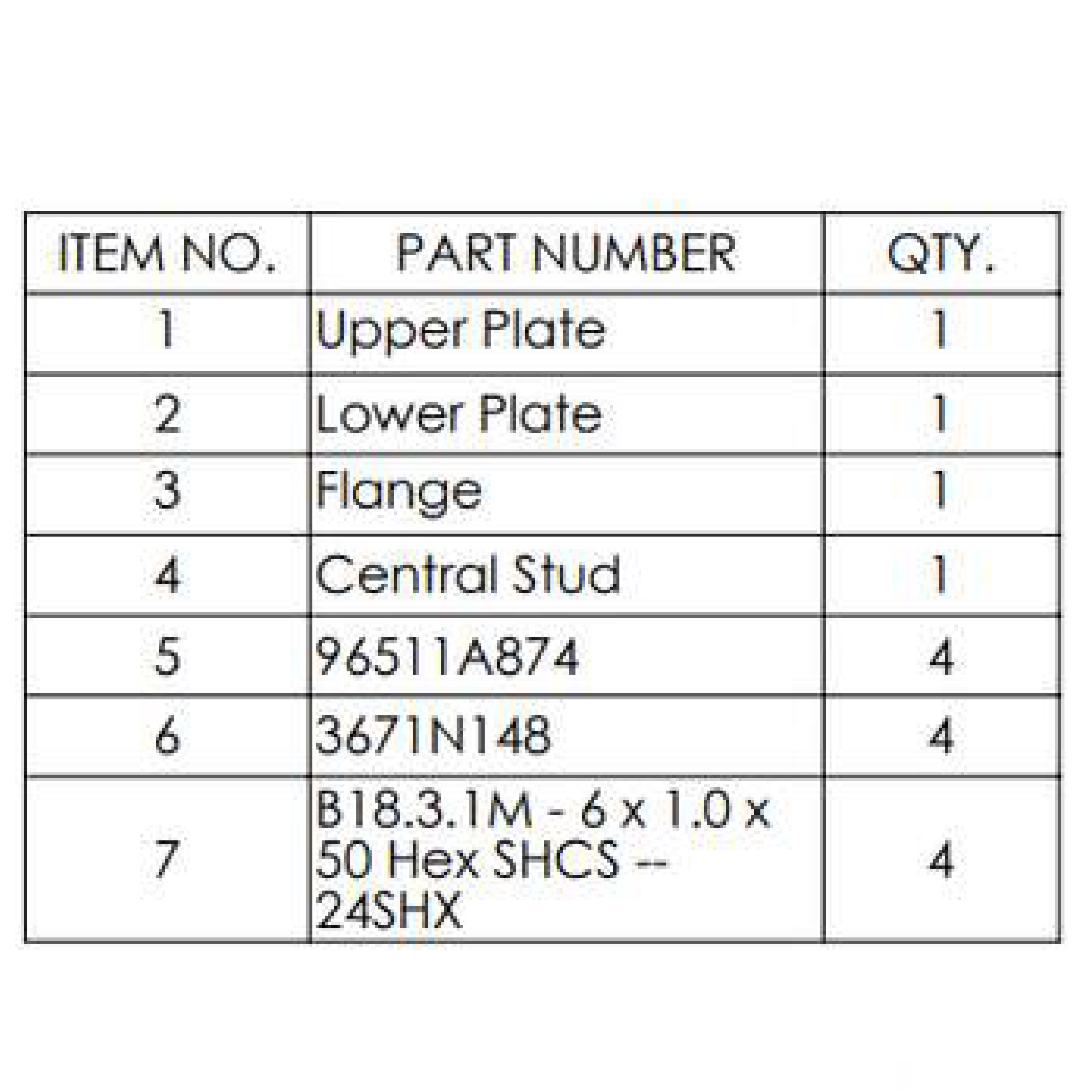

The jig consists of a two-plate configuration anchored by a central flange and aligned using precision-fit guide pins. The use of exploded views, constraint-based mating, and dimensional simulations helped refine the fixture's mechanical behavior under load. It was developed for easy assembly and disassembly, with visual documentation included to guide production line operators.

Special attention was given to the rotational mechanics, making the movement of bobbins smooth and collision-free. Motion analysis in SolidWorks enabled fine-tuning of the mechanism to prevent jamming and reduce energy loss.

Materials & Finishes

Corrosion-resistant stainless steel was selected for the main structure, with hardened tool steel for guide bushes and studs. Fasteners were based on ISO standards for global compatibility. A matte surface finish reduced glare on the workshop floor and enhanced operational visibility.

Key Benefits

This fixture dramatically reduces setup time and operator error, while ensuring exact drilling every time. It increases throughput, maintains accuracy across batches, and requires minimal training. The modular design also allows for quick adjustments when switching part types.

Target Audience & Use Case

This solution is ideal for manufacturing plants involved in flange production, custom part machining, and industries like oil & gas, construction, and heavy machinery, where consistent precision and reliability are critical.

Project Impact & Takeaway

The final fixture significantly improved workflow efficiency and product consistency. It empowered the client to scale production without compromising on quality or increasing labor intensity—delivering long-term savings and higher client satisfaction.

Project Summary

The Drill Jig and Fixture Design represents a significant advancement in manufacturing technology, combining precision engineering with practical automation. Through careful consideration of mechanical design and operational efficiency, we've created a system that not only meets but exceeds industry standards for drilling equipment.

The project demonstrates how modern engineering techniques and detailed simulation can revolutionize traditional manufacturing processes. By focusing on both performance and reliability, we've developed a solution that addresses the needs of various industries while setting new benchmarks for manufacturing excellence.

"The Drill Jig and Fixture has revolutionized our manufacturing processes. Its innovative design and high-precision capabilities have significantly improved our productivity and product quality."

Emily Thompson, Production Manager