Nerf Gun for 3D Printing

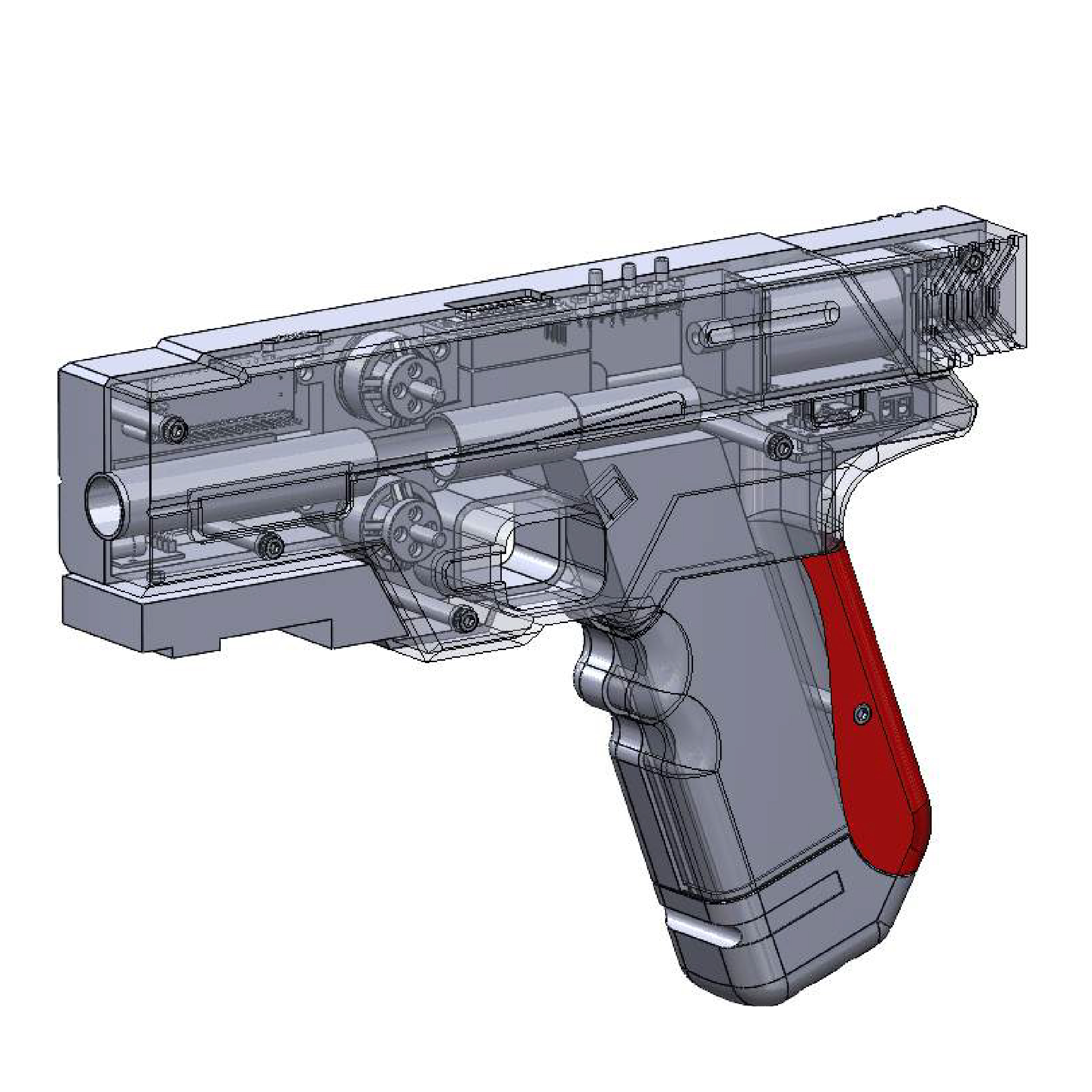

This project involved the design and development of a fully functional Nerf gun tailored specifically for 3D printing. The goal was to create a reliable, modular, and aesthetically sleek device that integrated various electronic components while remaining accessible for makers and enthusiasts. Built using SolidWorks, the design ensures that each internal part has its designated space and mounting point, creating a seamless balance between mechanical structure and electronic integration.

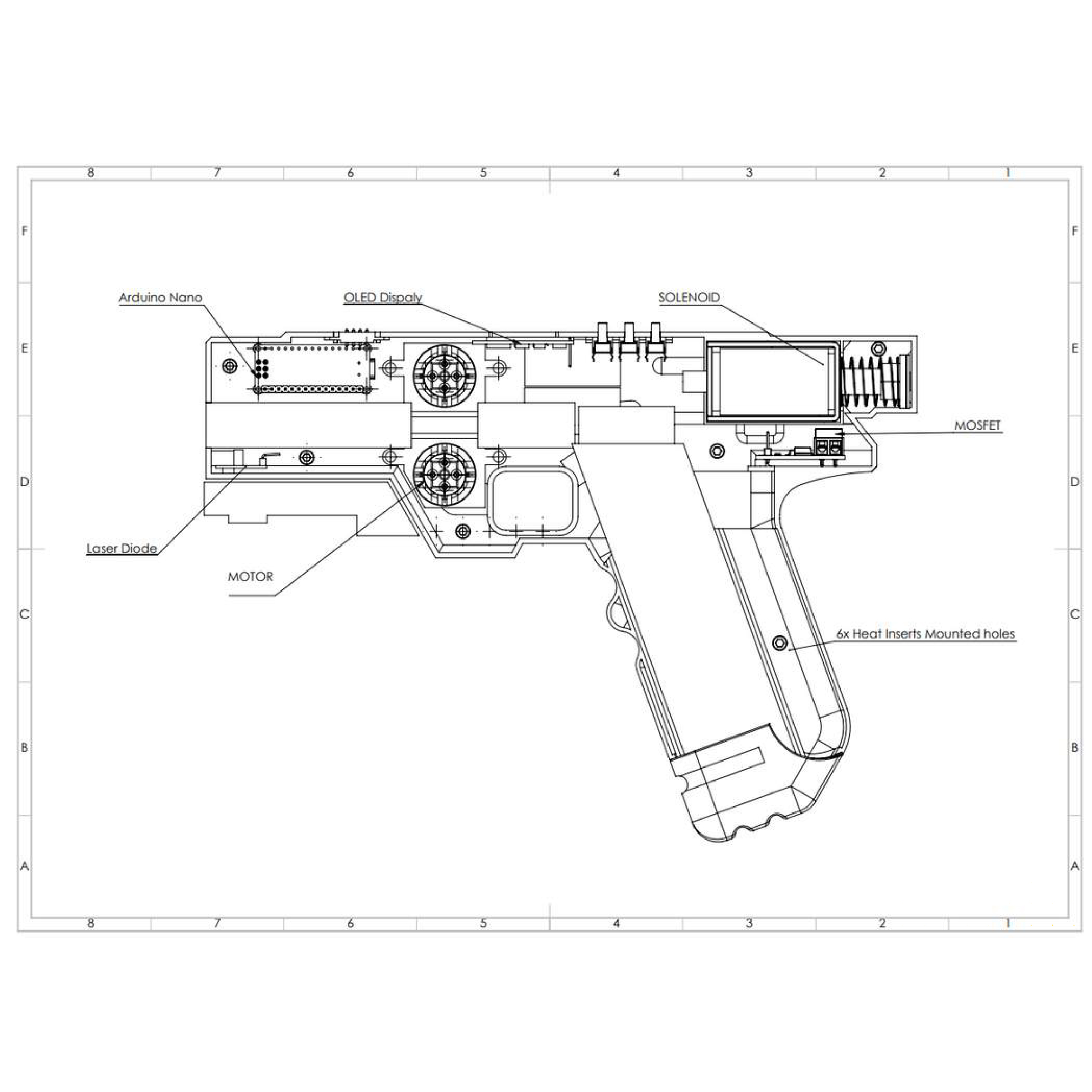

The Nerf gun was engineered with an ergonomic grip and compact housing, making it comfortable and user-friendly. Internally, the layout was optimized for component placement such as the Arduino Nano, solenoid mechanism, laser diode, motor system, and display module. Dedicated slots and channels were designed to ensure precise fitment and secure wiring.

The design supports snap-fit assembly with minimal external fasteners, maintaining a clean, robust exterior. Vents and internal clearances were carefully calculated to manage heat and mechanical motion effectively.

Materials & Finishes

The entire model was intended for 3D printing using FDM technology, with materials like PLA+ or ABS chosen for strength, ease of post-processing, and heat resistance. The design allows for multi-material printing, enabling selective use of flexible filaments in grip areas or transparent ones for display windows. The surface design was kept smooth with slight texturing around grip zones for better handling without compromising printability.

Key Benefits

This project merges mechanical design with embedded systems in a way that is both functional and educational. The modularity allows for easy upgrades or component swaps. The design is entirely 3D-printable without support structures, significantly reducing print time and post-processing. Clear wiring paths and labeled housing make assembly intuitive even for hobbyists. Moreover, the system allows programmable behavior through Arduino, adding an interactive and customizable user experience.

Target Audience & Use Case

This product is aimed at tech-savvy hobbyists, robotics learners, engineering students, and DIY makers who are interested in combining 3D printing with basic electronics. It's ideal for use in STEM classrooms, maker labs, robotics clubs, and personal experiments. Its customizability makes it suitable for teaching prototyping and real-world integration of mechanical and electronic systems.

Project Impact & Takeaway

The Nerf Gun project showcases the fusion of CAD, prototyping, and embedded design for hands-on innovation. It reflects Mechionix's ability to design functional hardware products that are fully ready for 3D manufacturing while supporting interactive technologies. The outcome is more than a toy—it's a working prototype platform that encourages learning, creativity, and practical application of multidisciplinary engineering.

Project Summary

The Nerf Gun for 3D Printing represents a significant advancement in maker technology, combining precision engineering with practical electronics integration. Through careful consideration of mechanical design and user experience, we've created a system that not only meets but exceeds expectations for educational and hobbyist applications.

The project demonstrates how modern engineering techniques and detailed simulation can revolutionize maker projects. By focusing on both performance and accessibility, we've developed a solution that addresses the needs of various educational and hobbyist communities while setting new benchmarks for 3D-printed interactive devices.

"The Nerf Gun project has revolutionized our STEM education approach. Its innovative design and educational value have significantly improved student engagement and learning outcomes."

Emily Thompson, STEM Educator