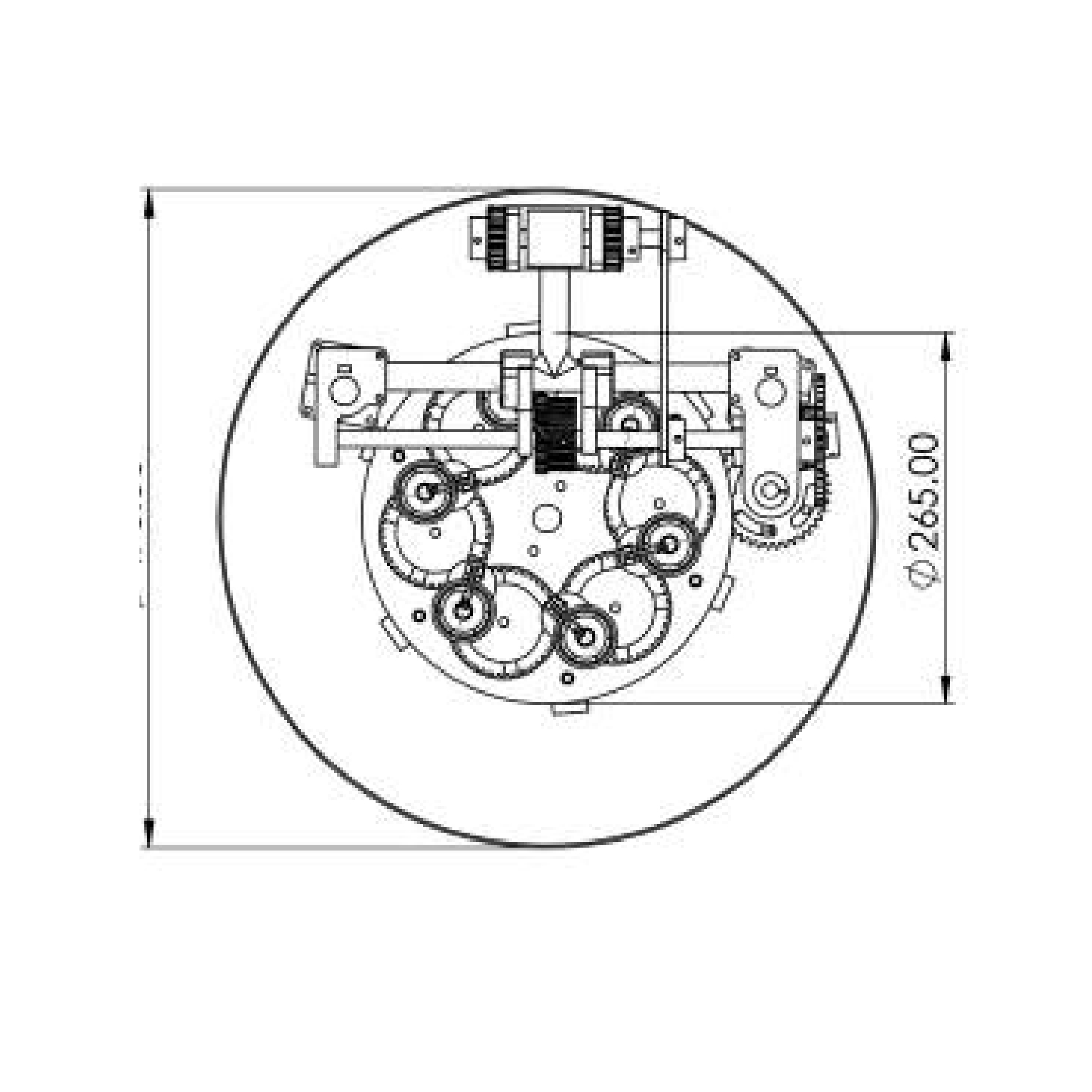

Six-Strand Braiding Machine

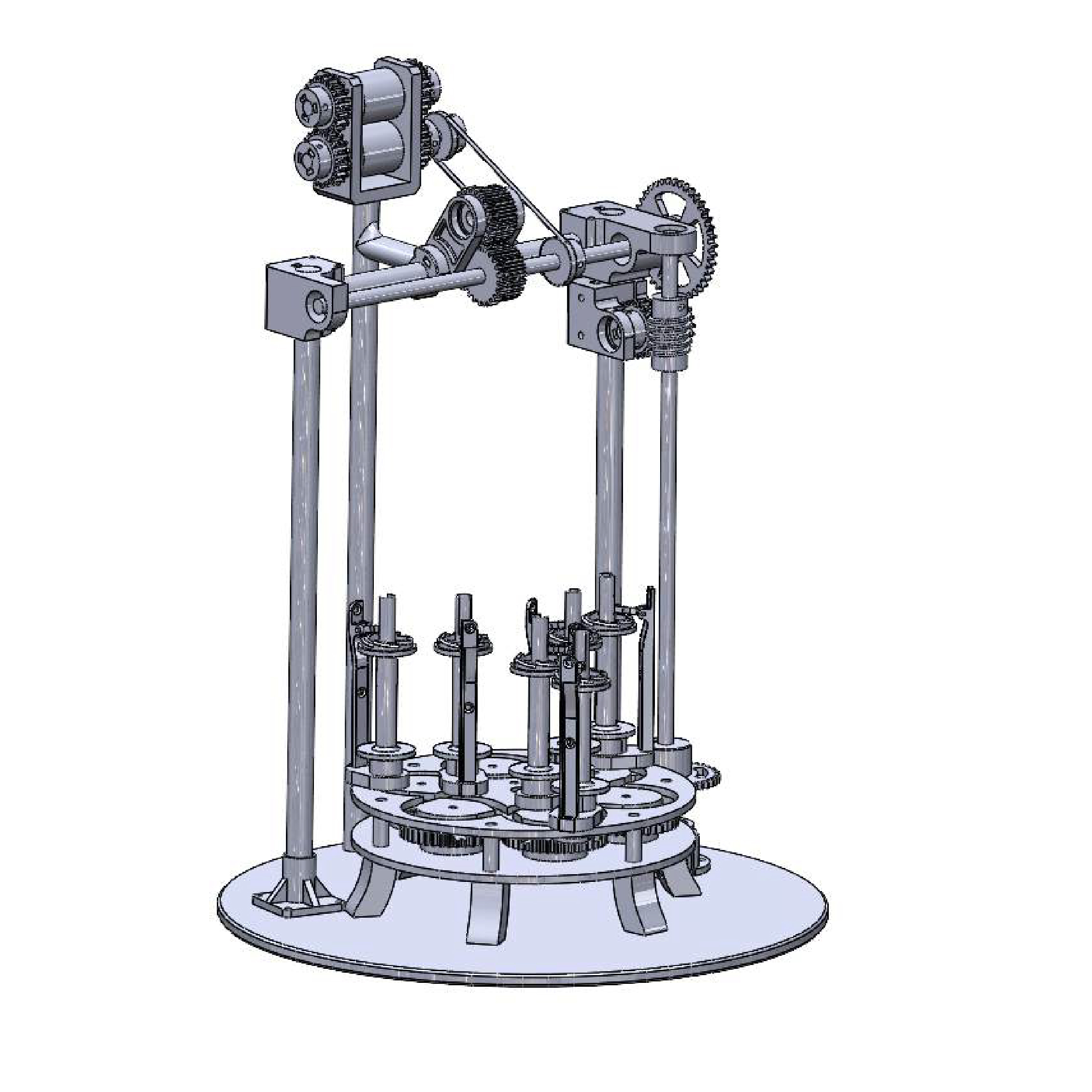

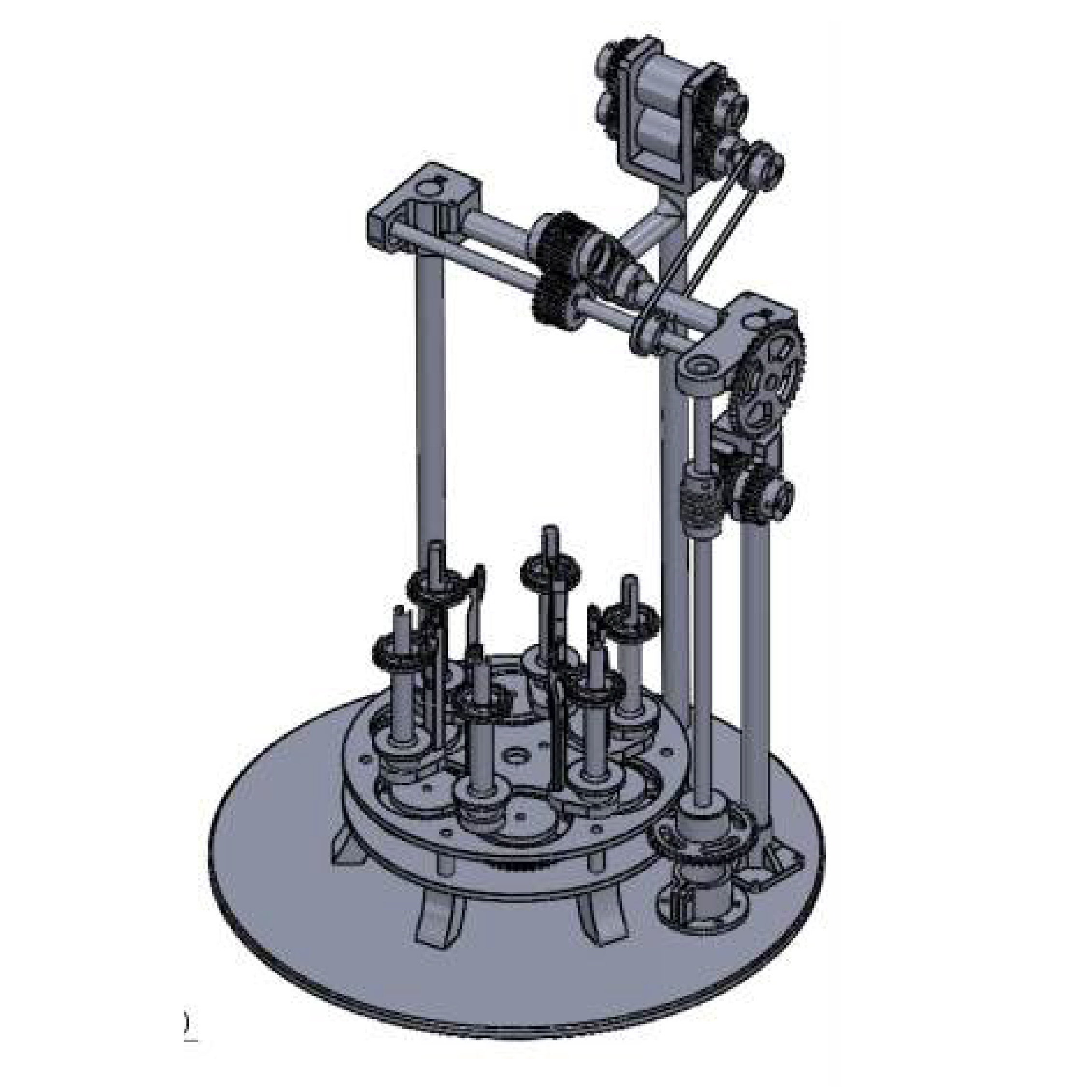

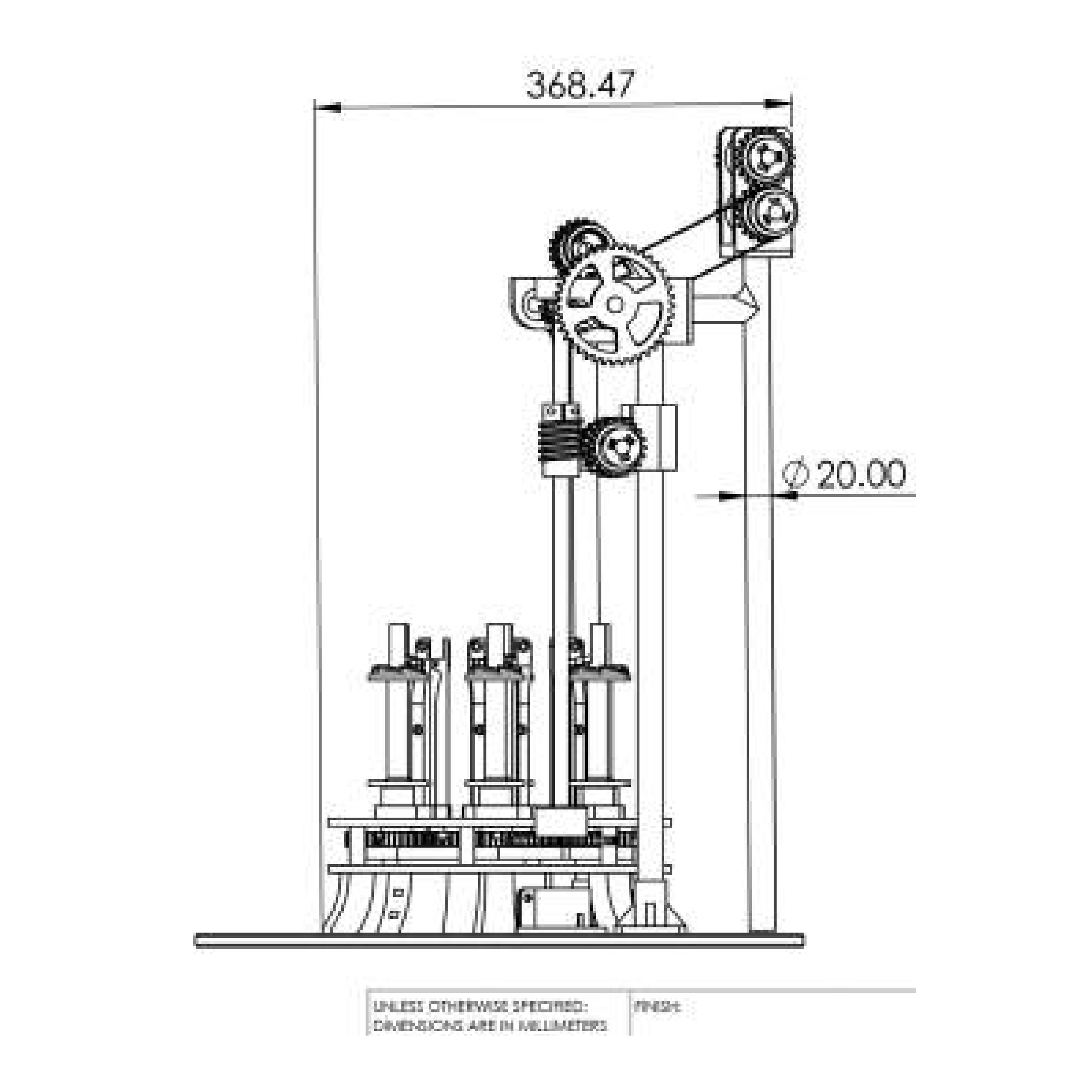

The Braiding Machine project was developed to create a precision system capable of producing six-strand braids with outstanding accuracy and consistency. Designed entirely in SolidWorks, the machine uses a rotating bobbin assembly to interlace strands of material, creating uniform braided structures. A detailed motion study was conducted to optimize the path of gears and strands, ensuring smooth mechanical operation. The goal was to deliver a machine that would streamline traditional braiding processes through modern engineering techniques.

The machine incorporates a modular, vertical layout to maximize stability and ease of assembly. The design features synchronized bobbin carriers, driven by a system of precision gears and belts, ensuring even tension across all strands during braiding. A compact footprint was prioritized without sacrificing the mechanical strength necessary for industrial use.

Special attention was given to the rotational mechanics, making the movement of bobbins smooth and collision-free. Motion analysis in SolidWorks enabled fine-tuning of the mechanism to prevent jamming and reduce energy loss.

Materials & Finishes

The structural frame was proposed to be manufactured using high-strength stainless steel for durability and resistance to corrosion. Moving components such as gears and spindles are intended to be produced from hardened steel, coated with anti-friction treatments to prolong life. Lightweight aluminum alloy was selected for non-load-bearing parts to reduce overall machine weight. All visible surfaces were designed for a clean, brushed metal finish to align with industrial aesthetics while ensuring easy maintenance.

Key Benefits

The braiding machine enhances production efficiency by automating complex manual processes with minimal intervention. Its precision gear-driven system ensures consistent braid quality, even during extended operation. Compact and scalable, it can be adapted for different materials and braid sizes, making it suitable for a wide range of industrial applications. The integrated motion study reduces operational risks like strand overlap and gear misalignment, significantly boosting reliability.

Target Audience & Use Case

This machine is ideal for manufacturers in industries such as textiles, composite materials, medical devices (like braided stents), and even aerospace sectors where braided reinforcements are needed. Small to medium-sized manufacturing plants looking for compact, high-precision braiding solutions would find this machine particularly beneficial. It supports custom braid geometries, making it a versatile addition to any high-end production environment.

Project Impact & Takeaway

By focusing on automation, compact design, and mechanical accuracy, the Braiding Machine project demonstrates how intelligent engineering can transform traditional manufacturing processes. It not only speeds up production and improves output quality but also significantly reduces operational errors and maintenance costs. This project showcases Mechionix's capabilities in combining mechanical innovation with detailed simulation, ultimately pushing forward the standards of modern manufacturing equipment.

Project Summary

The Six-Strand Braiding Machine represents a significant advancement in industrial manufacturing technology, combining precision engineering with practical automation. Through careful consideration of mechanical design and operational efficiency, we've created a system that not only meets but exceeds industry standards for braiding equipment.

The project demonstrates how modern engineering techniques and detailed simulation can revolutionize traditional manufacturing processes. By focusing on both performance and reliability, we've developed a solution that addresses the needs of various industries while setting new benchmarks for manufacturing excellence.

"The Six-Strand Braiding Machine has revolutionized our manufacturing processes. Its innovative design and high-precision capabilities have significantly improved our productivity and product quality."

Emily Thompson, Production Manager