3D Modeling & CAD

Mechionix offers end-to-end 3D Modeling and Computer-Aided Design (CAD) services that transform ideas into tangible digital prototypes. Whether you're at the ideation stage or heading into production, our team delivers high-precision models and technical drawings ready for prototyping, simulation, and manufacturing.

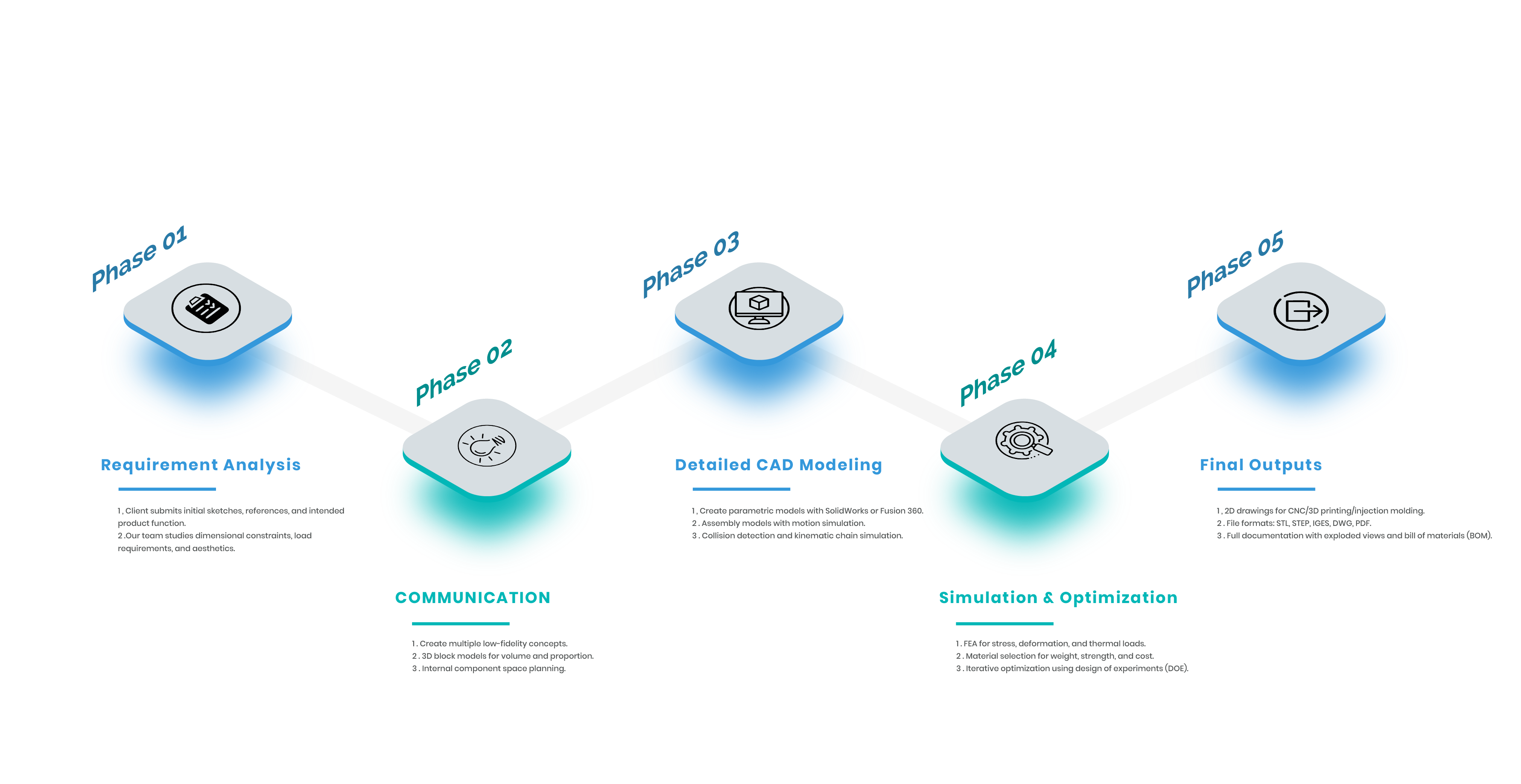

Work Process

Phase 1: Requirement Analysis

• Client submits initial sketches, references, and

intended product function.

• Our team studies dimensional constraints, load

requirements, and aesthetics.

Phase 2: Conceptual Design

• Create multiple low-fidelity concepts.

• 3D block models for volume and proportion.

• Internal component space planning.

Phase 3: Detailed CAD Modeling

• Create parametric models with SolidWorks or

Fusion 360.

• Assembly models with motion simulation.

• Collision detection and kinematic chain

simulation.

Phase 4: Simulation & Optimization

• FEA for stress, deformation, and thermal

loads.

• Material selection for weight, strength, and

cost.

• Iterative optimization using design of

experiments (DOE).

Phase 5: Final Outputs

• 2D drawings for CNC/3D printing/injection

molding.

• File formats: STL, STEP, IGES, DWG, PDF.

• Full documentation with exploded views and bill

of materials (BOM).

Industries Served

Visual Suggestions

• Before/after sketch to CAD comparison

• Time-lapse of assembly development

• Rendered walkthrough of the product

• Client submits initial sketches, references, and

intended product function.

• Our team studies dimensional constraints, load

requirements, and aesthetics.

• Create multiple low-fidelity concepts.

• 3D block models for volume and proportion.

• Internal component space planning.

• Create parametric models with SolidWorks or Fusion

360.

• Assembly models with motion simulation.

• Collision detection and kinematic chain simulation.

• FEA for stress, deformation, and thermal loads.

• Material selection for weight, strength, and cost.

• Iterative optimization using design of experiments

(DOE).

• 2D drawings for CNC/3D printing/injection molding.

• File formats: STL, STEP, IGES, DWG, PDF.

• Full documentation with exploded views and bill of

materials (BOM).