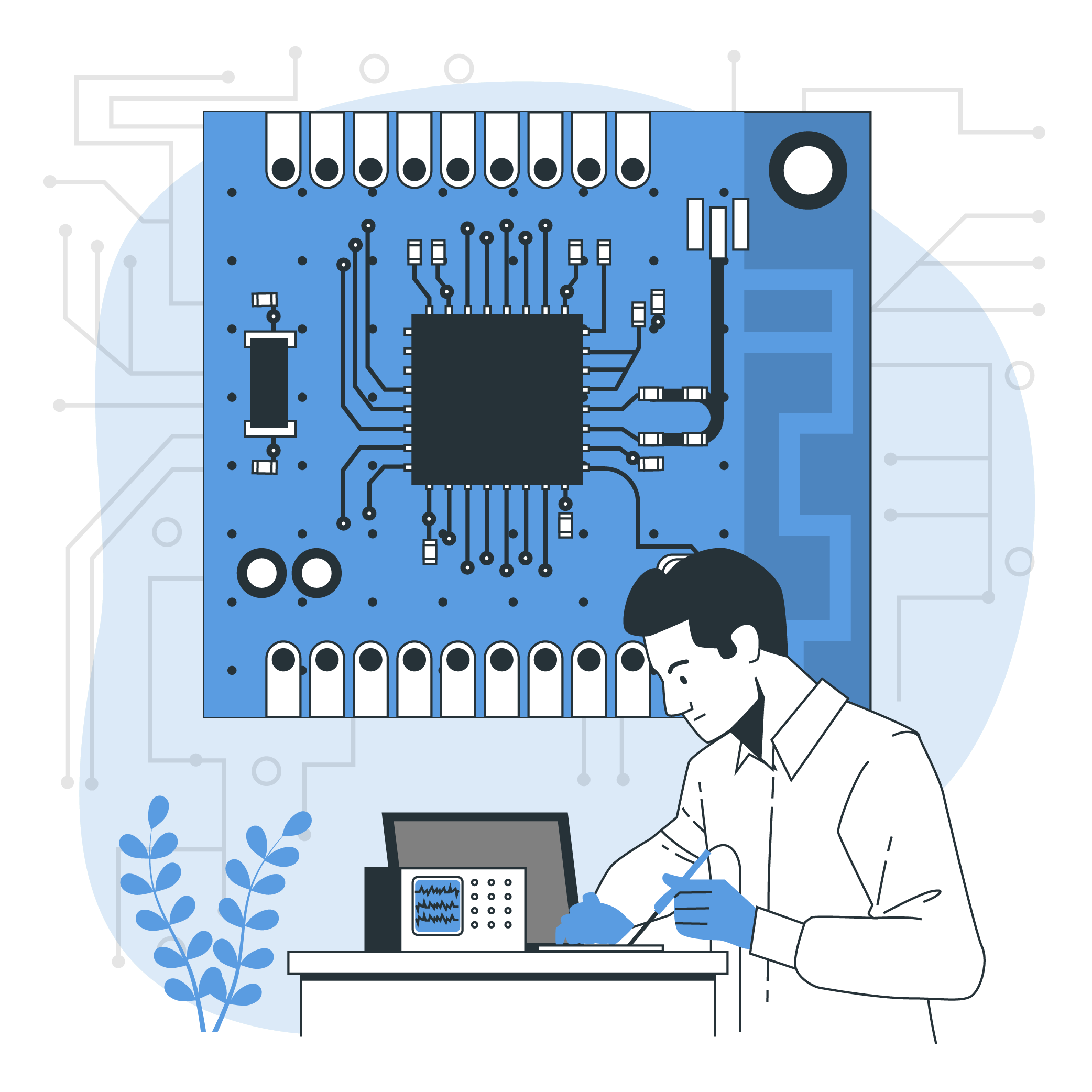

Electrical & Electronic Engineering

We offer high-precision electrical and electronic design services that support your products from schematic development to fully manufactured PCBs. Our electrical engineers work on complex analog/digital designs, power circuits, sensor interfaces, and more.

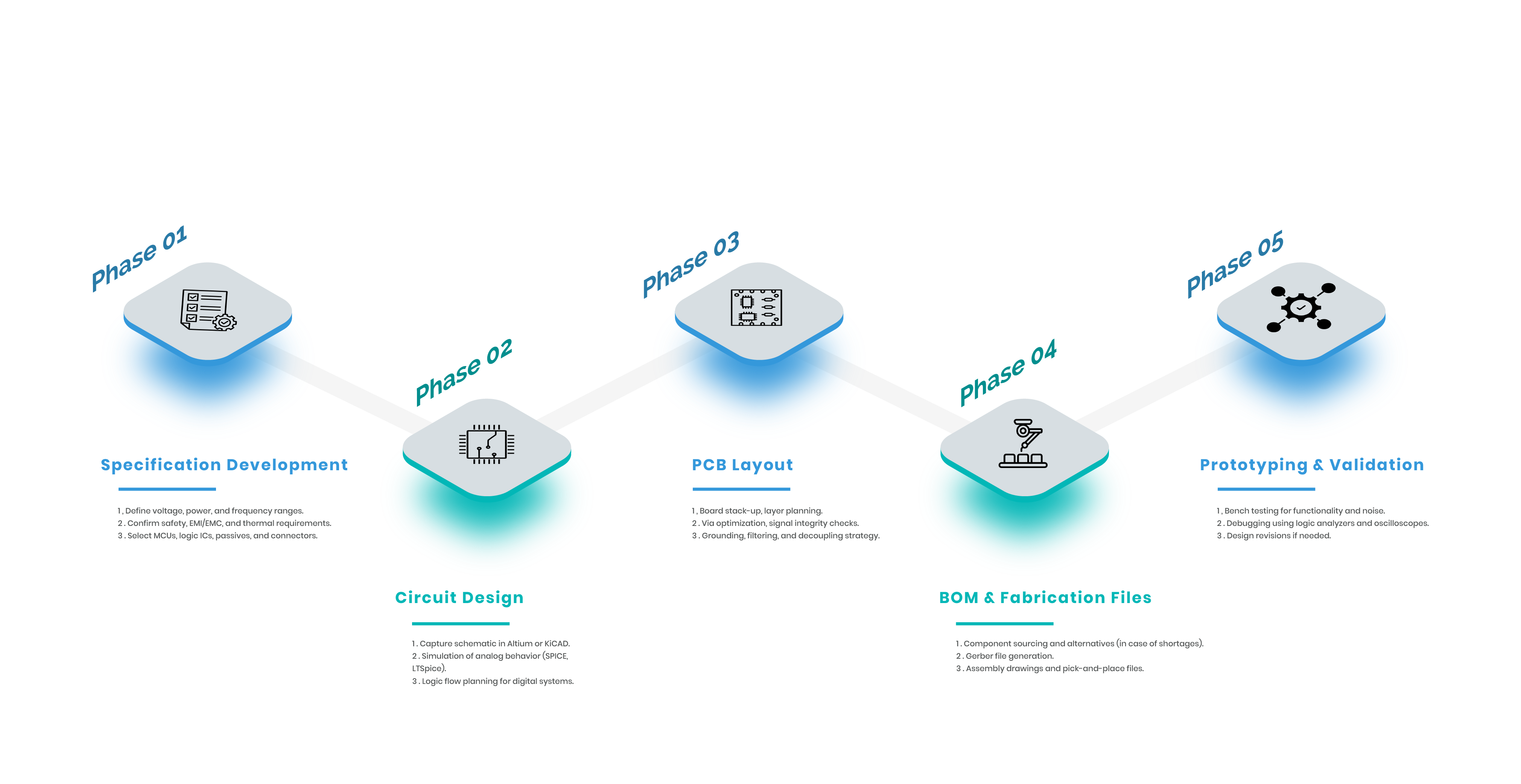

Work Process

Phase 1: Specification Development

• Define voltage, power, and frequency ranges

• Confirm safety, EMI/EMC, and thermal

requirements

• Select MCUs, logic ICs, passives, and connectors

Phase 2: Circuit Design

• Capture schematic in Altium or KiCAD

• Simulation of analog behavior (SPICE,

LTSpice)

• Logic flow planning for digital systems

Phase 3: PCB Layout

• Board stack-up, layer planning

• Via optimization, signal integrity checks

• Grounding, filtering, and decoupling strategy

Phase 4: BOM & Fabrication Files

• Component sourcing and alternatives

• Gerber file generation

• Assembly drawings and pick-and-place files

Phase 5: Prototyping & Validation

• Bench testing for functionality and noise

• Debugging using logic analyzers and

oscilloscopes

• Design revisions if needed

Industries Served

Visual Suggestions

• PCB 3D renders

• Screenshot of multi-layer routing

• Bench test images with instruments

• Client submits initial sketches, references, and

intended product function.

• Our team studies dimensional constraints, load

requirements, and aesthetics.

• Create multiple low-fidelity concepts.

• 3D block models for volume and proportion.

• Internal component space planning.

• Create parametric models with SolidWorks or Fusion

360.

• Assembly models with motion simulation.

• Collision detection and kinematic chain simulation.

• FEA for stress, deformation, and thermal loads.

• Material selection for weight, strength, and cost.

• Iterative optimization using design of experiments

(DOE).

• 2D drawings for CNC/3D printing/injection molding.

• File formats: STL, STEP, IGES, DWG, PDF.

• Full documentation with exploded views and bill of

materials (BOM).

.png)